Software and Business Systems

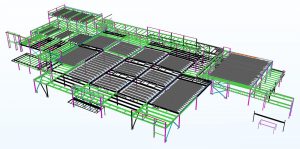

In the realm of structural steel and metal fabrication, Stone Bridge has remained committed to staying on the technological leading edge. Believing that software tools radically affect productivity, Stone Bridge has invested heavily in software products with development attitudes that mimic their own. Engineering and detailing is largely provided in-house with several stations of Tekla detailing software augmented with the most current versions of AutoCAD. This means detailing time is dramatically cut and response to design changes is immediate. Our engineering capabilities save your project time and money.

In the realm of structural steel and metal fabrication, Stone Bridge has remained committed to staying on the technological leading edge. Believing that software tools radically affect productivity, Stone Bridge has invested heavily in software products with development attitudes that mimic their own. Engineering and detailing is largely provided in-house with several stations of Tekla detailing software augmented with the most current versions of AutoCAD. This means detailing time is dramatically cut and response to design changes is immediate. Our engineering capabilities save your project time and money.

Information and historical data is one of Stone Bridges’ greatest assets. Historical data generated over a quarter century is brought together thru the use of newly implemented StruMis software systems. StruMis software manages our estimating, production control and project data while our engineering and detailing departments utilize a variety of modern CAD and 3-D modeling systems. In house engineering capabilities allow for efficient connection design which accelerates the modeling processes. Recently implemented bar coding systems maintain shop production controls and shipping controls. From the latest connection design software to steel detailing software, nothing is left to chance. Utilizing 3-D modeling software, wire frame models of the clients’ buildings are generated and checked. Once detailed and approved, CAM data is electronically downloaded to any of the shop floor machine tools for immediate fabrication.

Machine Tools

Machine tools are key in our ability to produce accurate weldments and shipping pieces on time and with the least possibility for error. Our inventory of equipment is constantly changing as we re-tool our metal fabrication shop with cutting-edge machine tools. Stone Bridges’ shop floor contains a large selection of CNC tools from drill, coping, and angle lines, to plasma and oxy-fuel cutting, shear, brake, and a host of NC or manually controlled machine tools.

The following is a list of machine tools and other structural steel and metal fabrication equipment.

CNC and NC Machine Tools

- Ficep Model 1103 CNC drill line with SCS 115 band saw

- Ficep Model 1202 CNC drill with plasma/oxy fuel coping system

- Controlled Automation ABL-100 143 ton CNC single-shear angle fabrication system

(angle 8″ x 8″x 1″ and 1″ x 8″ Flat Bar capacity) - Gemini Hypertherm HPR 260 CNC plasma/oxy-acetylene cutting table 10′ x 20′ x 4″ plate capacity

- Controlled Automation 2AT-175 CNC Plate Punch (175 tons)

- Hydra Power NC controlled plate shear – 3/4″ x 10′ capacity

- Hydra Power NC controlled press brake – 400 ton x 12′ capacity

Other Machine Tools

- 585 Ton capacity Cambco cambering machine, sections to W40

- Peddinghaus single end punches to 175 ton

- Peddinghaus super 16 iron worker

- 8,000 sq.ft. climate controlled paint bay (and AISC sophisticated paint endorsement)

- 8-wheel Wheelabrator – Automatic sandblast machine 4’x8′ opening

- Sandstorm sandblasting setup with Atlas 185 comp.

- Grayco Pro 2300/3500/4500 and airless paint pumps (application of primers, epoxy, and polyurethane)

- 13 Overhead bridge cranes with lifting capacities to 10 ton.

- 33,000 lb, 24,000 lb, 15,000 lb and 11,000 lb fork trucks

- Ercolina pipe rolling and mandrel pipe bending system – 2″ pipe capacity

- Almi Pipe Profiling System

- Lincoln and Miller wire feed MIG and TIG welders

- Full time AWS certified welding inspector and quality assurance department